Our markets

Power distribution

The power distribution industry supplies a significant amount of copper and aluminium flat bar products (busbar) to distribute high current electricity in applications ranging from switchgears to busway within industrial and commercial properties. These products can be processed using our punching, bending and end forming machines.

Vaski solutions are all truly innovative with the only all electric flat bar range on the market, the only automatic tool change bending machine and the only fast, safe, easy to use end forming machine on the market. Furthermore the housing and cabinets can be built using blanks from our blanking and slitting lines with multi-coil blanking providing the ultimate in terms of material flexibility.

Power generation

The power generation industry requires copper bar and extrusion to be processed into copper coils. Vaski has created a truly differentiating new product that eliminates the requirement to braze each corner of the coil allowing coils to be created automatically using our innovative coiling technology saving significant process time and money for our customers.

Naturally in and around generators tends to be significant amounts of standard busbar that can be processed by Vaski busbar processing machines.

Metal producers & Steel service centers

From coil to coil-strips and cut blanks, Vaski can offer a wide range of efficient solutions in blanking and slitting. From manual operated simple cut-to-length to fully automated factory level system. In particular the multi-coil technologies and the automatic coil storage solutions are quite unique and supportive to this industry.

Furthermore, our bar end finishing machine has proved to be interesting to bar stockists and producers as is flexible to end finish both flat and round bar automatically with no setting adjustments required.

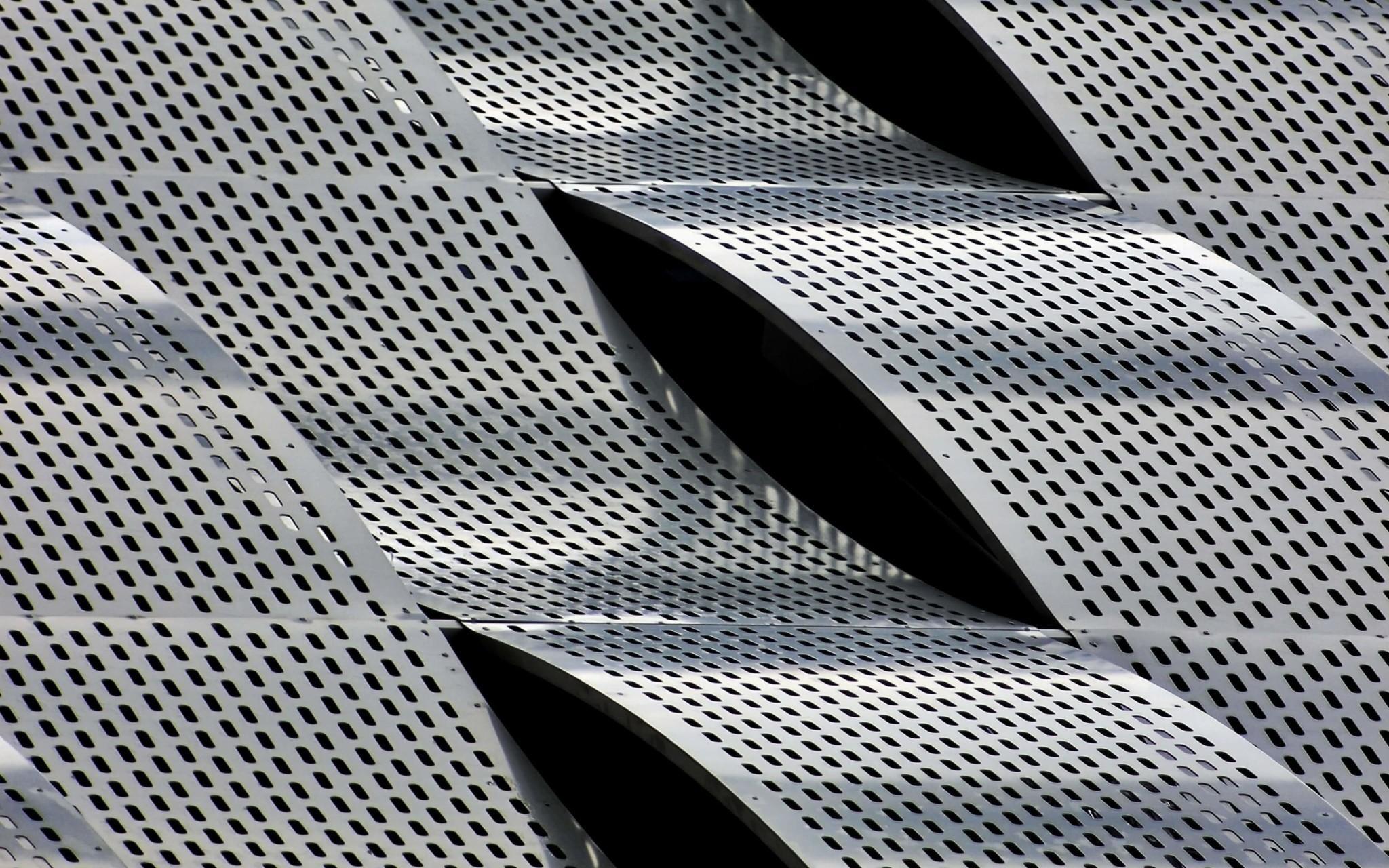

Construction materials

Construction materials sector is a core market for most of our machines in various applications. Our punch and shape machines are flexible to punch and end shape both flat bar and profiles for window and door frames as well as various other construction material long product components.

Furthermore, our blanking and slitting lines are very popular in the roofing and facades market being one of our largest target markets for this product. Our machines are able to provide great quality blanks and slit solutions with high quality straightening and cutting of components as well as connecting to other processes such as presses or roll forming machines for guttering and roof plates and other contruction material applications (such as lighting and ceiling panels inside buildings).

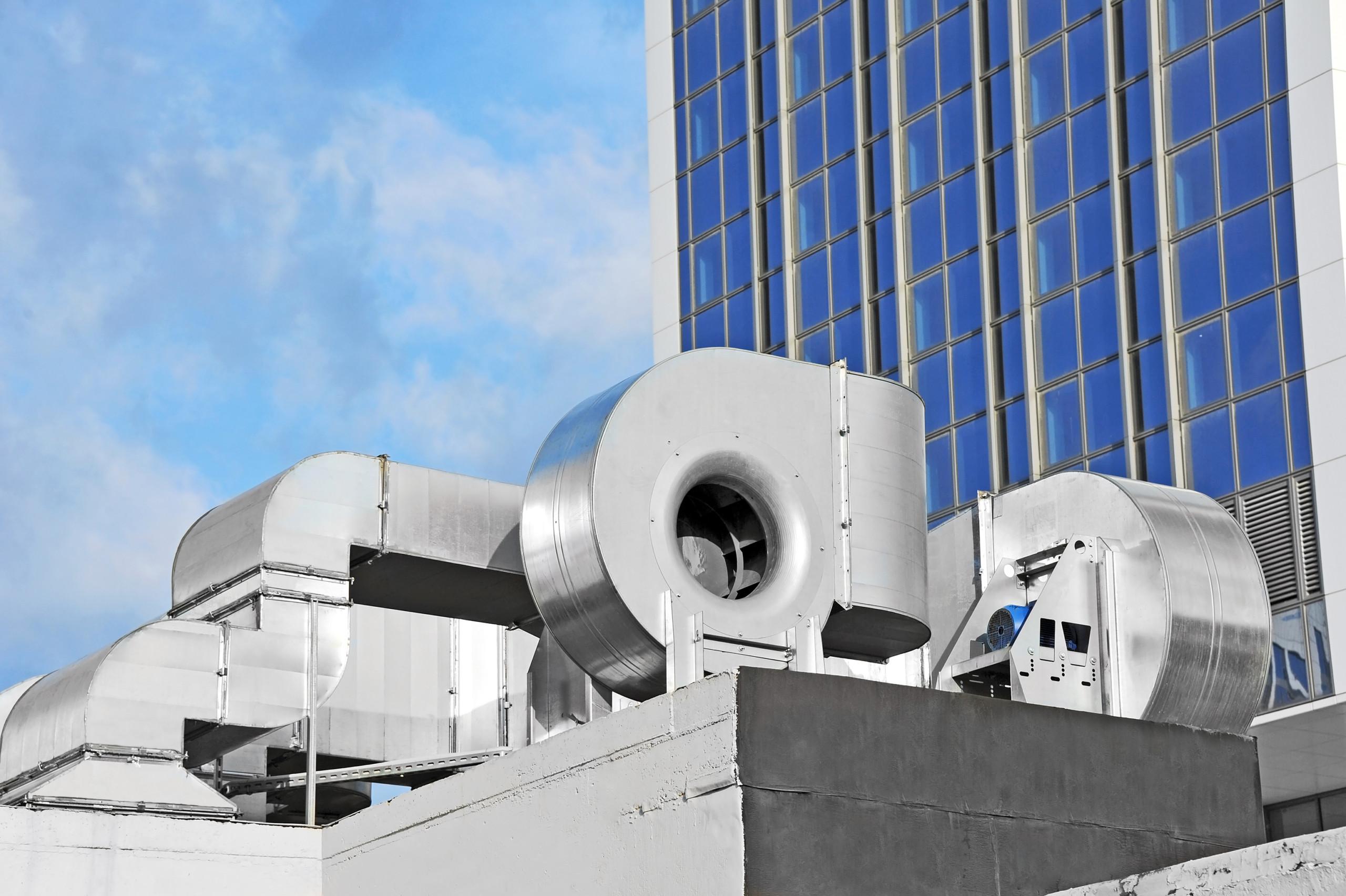

HVAC

HVAC is a market in which Vaski excels, supplying blanking and slitting products to support the production of the majority of HVAC components (which themselves are predominantly sheet metal).

Furthermore, Vaski has maintained a special focus on this important industry having invented numerous special solutions for this industry over the years.

Special machines for HVAC component manufacturing have long been known by Vaski:

– Forming a flange and punch holes on to it for axial fan housing on same production phase

– Mangle for radial fan shroud forming

– Pittsburg seam closing machine for radial fan housing

– Radial fan inlet cone trimming and hole punching on same machine

– Deep draw servo press for sheet metal

Sheet metal manufacturers

Advanced Vaski coil cut-to-length and slitting solutions gives flexibility to your services when you can automatically change the coil and by that smaller batches ensuring stock is minimised and profits maximised.

Vaski cut to length lines have been shown to save on average 30% of material costs for our customers through savings from lower prices due to sourcing directly from the steel producer rather than service centres (also eliminating the material handling costs and additional transportation at the service centre) as well as savings through nesting improvements through blank selection.

Machine manufacturers

Vaski is open to integrate other machine manufacturers as well as be integrated to other machines. Furthermore, Vaski is accustomed to partnering with other machine manufacturers to build customised automation and customised machine solutions for other machinery manufacturers tailored to their specific requirements.

Vaski can apply their leading technology and solutions to help other machine manufacturers and other industries gain similar benefits that Vaski are supplying to the busbar and blanking industries.